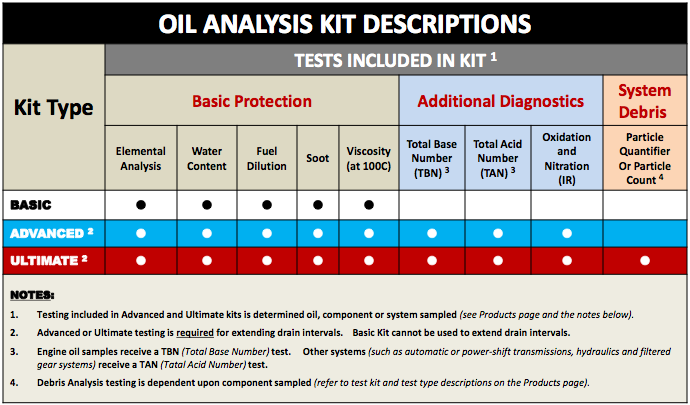

Oil Analysis Kit Description

Basic Oil Analysis KitIncludes Metals Analysis (wear metals, contaminant metals and additive metals), Viscosity at 100C , Water Content and Soot Content

Advanced Oil Analysis Kit

May be used for engines, transmissions, gear boxes, differentials, or refrigerator truck circulation motors.

Includes all of the tests included in the Basic Oil Analysis Kit plus TBN (Total Base Number) for engine oil samples, TAN (Total Acid Number) for non-engine oil samples and Oxidation/Nitration.

Ultimate Oil Analysis Kit

Recommended for Heavy Duty fleet analysis where filtration information is also required.

Includes all of the tests included in the Advanced Oil Analysis Kit plus an evaluation of either iron wear or general system debris. Note: Testing performed to evaluate system debris and/or iron wear is based on component type and/or oil type (see System Debris definitions below). Where filter media size is known, the kit can be used to evaluate whether or not filters are providing expected filtration by measuring system particles and them to filter media size. As with the Advanced Oil Analysis Kit, this kit may also be used to extend drain intervals in addition to measuring system debris.

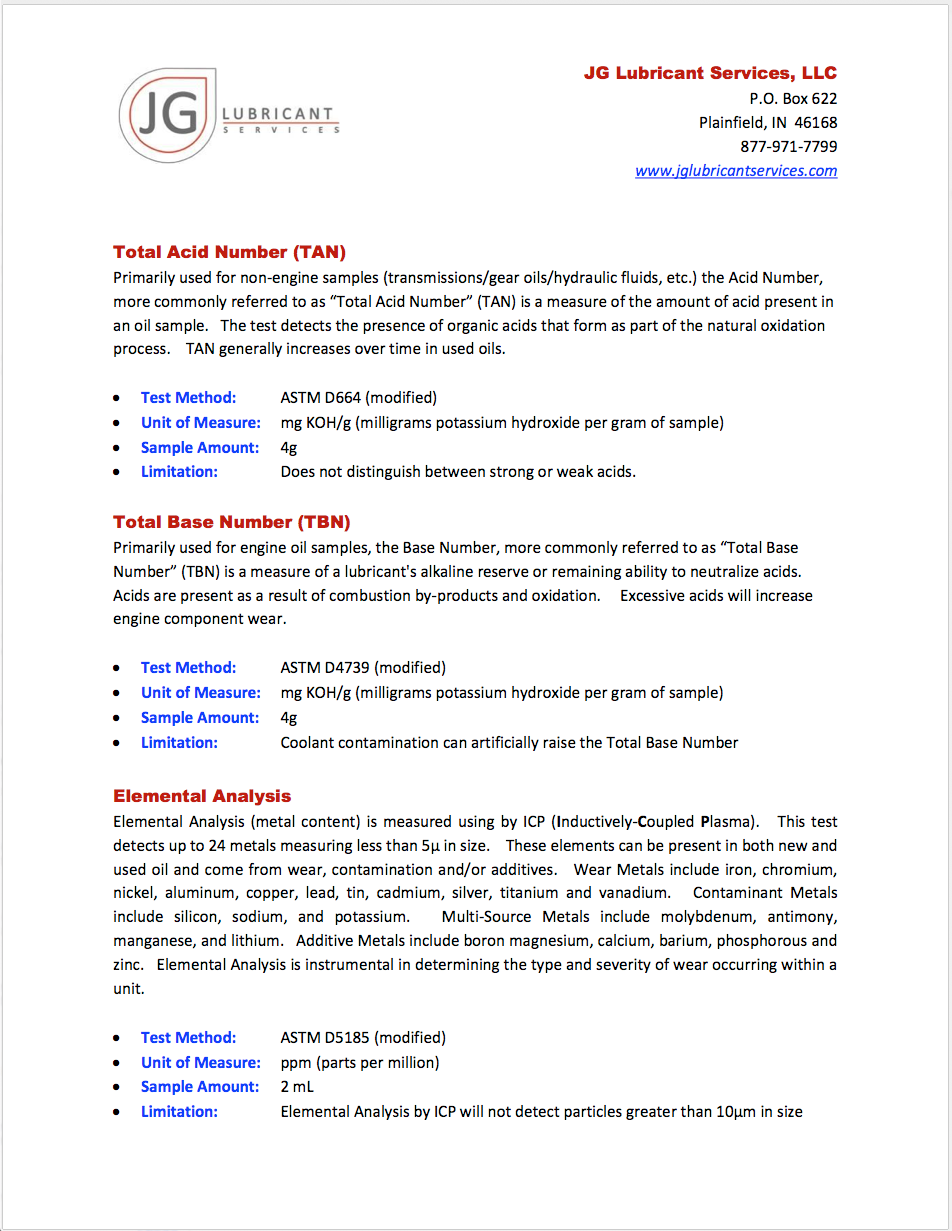

- Particle Quantifier (PQ Index) - Engine oil samples receive Particle Quantifier testing with "PQ Index" reported. The Particle Quantifier exposes the oil sample to a magnetic field. The presence of any ferrous (iron based) metal causes a distortion in the field, which is represented as the PQ Index. PQ Index correlates well with Direct Read Analytical Ferrography (large). PQ does not provide a ratio of small to large ferrous particles; however, if the PQ Index is smaller than the Iron as shown in the ICP wear metal data (ppm), then it's unlikely there are any particles larger than 10 microns present in the sample. If the PQ Index increases dramatically while the ICP Iron data (ppm) remains constant or decreases, then it's likely that larger iron particles are being generated and add-on Analytical Ferrography testing may be recommended.

- Particle Count and ISO Cleanliness Code - Non-engine samples from filtered systems, such as hydraulics, turbines, compressors, automatic or power shift transmissions, recirculation systems and gear systems (with a fluid viscosity of less than ISO 320) will recieve Particle Count testing and a calculation for ISO Cleanliness Code (per ISO 4406). The unit of measure is for Particle Count is (#particles per milliliter). Results are reported in the following micron size ranges: >4 µm, >6 µm, >10 µm, >14 µm, >21 µm, > 38 µm, >70 µm and >100 µm. ISO Cleanliness Code is a unit-less number based on the Particle Count results in the 4, 6 and 14 µm Particle Count ranges. For example, an ISO Cleanliness Code of 19/16/13 means the sample contained between 2,500 and 5,000 particles >4 µm, between 320 and 640 particles >6 µm and between 40 and 80 particles >14 µm.

Coolant Analysis Kit Description

Coolant Analysis KitIncludes the following tests: Visual (color, oil, fuel, magnetic precipitate, non-magnetic precipitate, and odor), pH, Glycol, Freezing and Boiling Points, Nitrite, Specific Conductance, Foam, Corrosion Metals, Contaminants and Inhibitors, SCA# (Supplemental Coolant Additives), and Total Hardness

Vacuum Pumps

JGVP01 Oil Analysis Vacuum PumpUse the JGVP01 Vacuum Pump for engine, transmission, or gearbox sampling through the dipstick or access hole.

Instructions: Remove the sample jar cap. Attach the tubing to the Vacuum Pump and insert the tubing into the oil reservoir through the dipstick tube or access hole. Actuate the pump until the oil sample comes up the tubing and fills the sample jar approximately 3/4 full. Throw away the tubing section after the sample is taken (never reuse the tubing section). Put the cap on the sample jar. Fill out the sample jar label completely and attach it to the sample jar. It's that simple!!

Note: Always use a fresh tubing section for any oil sample.

Use the JGVP02 Vacuum Pump for coolant sampling from the coolant reservoir.

Instructions: Remove the sample jar cap. Attach the tubing to the Vacuum Pump and insert the tubing into the coolant reservoir. Actuate the pump until the coolant sample comes up the tubing and fills the sample jar approximately 3⁄4 full. Throw away the tubing section after the sample is taken (never reuse the tubing section). Put the cap on the sample jar. Fill out the sample jar label completely and attach it to the sample jar. It’s that simple !!

Note: Always use a fresh tubing section for any oil sample.

JG Lubricant Services supplies used oil analysis kits to test different types of equipment and a host of different applications including engines, transmissions, differentials, generators, refrigeration equipment (reefer units) and APUs (Auxiliary Power Units). Our car oil analysis kit and other products are designed to meet your needs and provide both individuals and fleet managers with complete data that shows the overall health of both the oil and the host equipment.

Our oil analysis kit is packaged in either single or 3-packs for individual sales through the online store. Oil analysis kits are also available in convenient 10-packs for fleet use and quantity discounts on all of our oil analysis kit types, are available from orders of 50 kits up to 1000 kit orders.

The JG Lubricant Services oil analysis kit is designed to meet all your equipment maintenance needs and ensures your equipment remains as “worry free” as possible. In an effort to meet all system demands, we have developed and currently market (3) levels of testing including our Basic oil analysis kit, an Advanced oil analysis kit and an Ultimate oil analysis kit. These used oil analysis kits can test engines, transmissions, differentials, generators, refrigeration equipment (reefer units) and APUs (Auxiliary Power Units). Our oil analysis service and lubricant analysis data gives you peace of mind in knowing your equipment is protected through scientifically proven testing and analysis methods.

So, why not move from your current preventative maintenance program to a “predictive maintenance” program through JG Lubricant Services. Our car oil analysis kits and other products can get you where you need to be in order to maximize savings and maintain equipment in tip top condition. It’s the only way to ensure you don’t get caught fixing unanticipated problems that caught you “off guard” and that leave your equipment off the road and in the repair shop where it’s not ready for use and, in the case of a commercial vehicle, not making revenue.